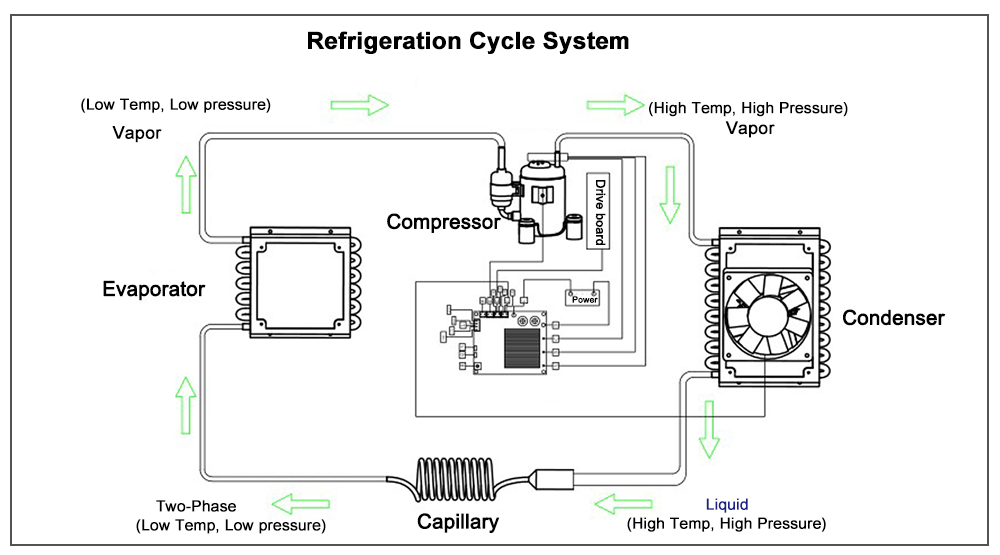

1. Basics of Cooling Systems

The refrigeration units consist of 4 basic components, compressor, condenser, capillary/electronic expansion valve, and other electronic parts(filter drier, oil separator, etc.). It applies the temperature and phase change of the refrigerant to achieve the cooling cycle.

2. Working Principle of Cooling Systems

After each part of the refrigerationa and air conditioning unit is connected through the copper pipe, it is completely sealed to form a pipeline. The pipeline is sealed into the “refrigerant”. The welding work is to weld the pipeline to prevent leakage, so that the refrigerant in the pipeline can flow properly. In this way, it can improve the quality of air conditioning, reduce the manufacturing cost and decrease the impact on the environment.

3. Components of Air Conditioning Systems

4. The Role of Each Components

> Compressor: make the refrigerant in the compressor in a high temperature and high-pressure state, in order to liquefy the refrigerant. And the refrigerant can be circulated in the pipeline. The compressor should fill with lubricating oil to improve lubrication and reduce friction when the compressor is working, and achieving cooling tasks.

>Filter: Filter impurities, dry moisture.

>Heat exchanger: cooling refrigerant;

>Four-way valve: cooling and heating conversion;

>Pipeline system: refrigerant circulation pipeline;

>Valve plate: switch connected to the indoor unit;

>Electronic expansion valve: control refrigerant flow size.

5. Welding Keypoints

Point ①: Basic notes

> Structure of welding torch and spot inspection method of injectivity torch

> Spot inspection method of gas bottle and gun belt

> Use method of each part of welding torch

> Pressure of Acetylene, oxygen and nitrogen

O2:0.2~0.5MPa;

C2H2:0.05~0.1MPa

N2:0.2~0.5MPa;

>Nitrogen replacement, continuous charge <0.1MPa

Color of Acetylene, oxygen and nitrogen hose

O2:Blue

C2H2:red

N2: Black

> (Protective glasses, gloves, and long-sleeved work clothes)

> Use and structure of pressure reducing valve Precautions for changing gas bottles The function, principle and caused reason for temperer.

Point ② Heating method.

>Heating method

>Torch ignition and flame adjustment method

>Heat the copper tube until the color of the tube that has reached 740 ~ 840 ° C can be visually judged.

>Actually experience the temperature at which the copper tube melts (holes appear). (1038℃)

>Maintain welding temperature (740 ~ 840℃) for 10 seconds.

Point ③ Solder adding method

>Use 1.6mm×0% of solder

>Position of solder adding (opposite to the heating method)

>Timing of solder adding

>Solder dripping phenomenon (dripping caused by temperature difference)

Point ④ Welding practices (outside the production line)

>Use 4.95mm and 4.76mm

>Prepared tools

>Bench vise (fixing the pipe), small iron saw, cloth sandpaper, file

Point ⑤ Welding practices (outside the production line)

>Firstly practice with 4.95mm and 4.76mm copper tube parts

>Perform at 1 place/2 units at first, and then gradually increase the frequency.

>Do not instruct in the processing state, but by temperature.

>Characteristics of welding

>Copper tube connection

>Melting point of the solder: 435℃

>Solder flows by capillary phenomenon.

>Steps of welding operation

>Optimum clearance

>Cleanliness of base material and material

>Proper tube connection and retention

>Make it flowing after melting by heating

>Surface cleaning after welding

>Temperature of the weld and proper temperature

Welding rod type

| Welding Rod Type | Ag Content |

|---|---|

| BCUP-3 | 5% |

| BCUP5 | 15% |

| BCUP6 | 2% |

| BAg30CuZn | 30% |

Role of Flux

1. Thermal stability

2. Wettability

3. Cleaning

4. Isolate the air, prevent reoxidation, and do not produce slag inclusion.

Type of flames:

>Neutral flame: oxygen to acetylene volume ratio of 1~1.2; Copper

>Carbonization flame: oxygen to acetylene volume ratio < 1; Aluminum >Oxidation flame: Oxygen to >acetylene volume ratio > 1.2; Iron-iron welding

Welding Practical Skills

We are your trusted partner in China for high-quality copper tubing solutions. We offer an extensive range of durable and corrosion-resistant copper pipe & tubing for refrigeration and air conditioning and other various industries, including pancake coils, straight length copper pipe, capillary copper tube, innger grooved copper tubing, level wound coil, insulated tube set, copper fittings and so on. Contact us today to discover how we can meet your specific project requirements.