Today, the demand for efficient cooling solutions has never been more pressing. Whether you’re managing heat in high-performance electronics, maintaining precise temperatures in medical devices, or simply keeping your home cool during summer, micro cooling systems have become an essential tool.

At Moir Cooling (referred to MOIR), we specialize in providing cutting-edge miniature compressor cooling technology that meets the unique demands of various applications. In this article, we’ll explore everything that you should know about the micro cooling systems, their importance, categories, working principles, selection tips, future trends, and so forth.

Understanding Micro Cooling Systems

Micro cooling systems, also known as miniature cooling systems (MCS), represent a significant advancement in the field of cooling technology, particularly for applications requiring compact and efficient cooling solutions.

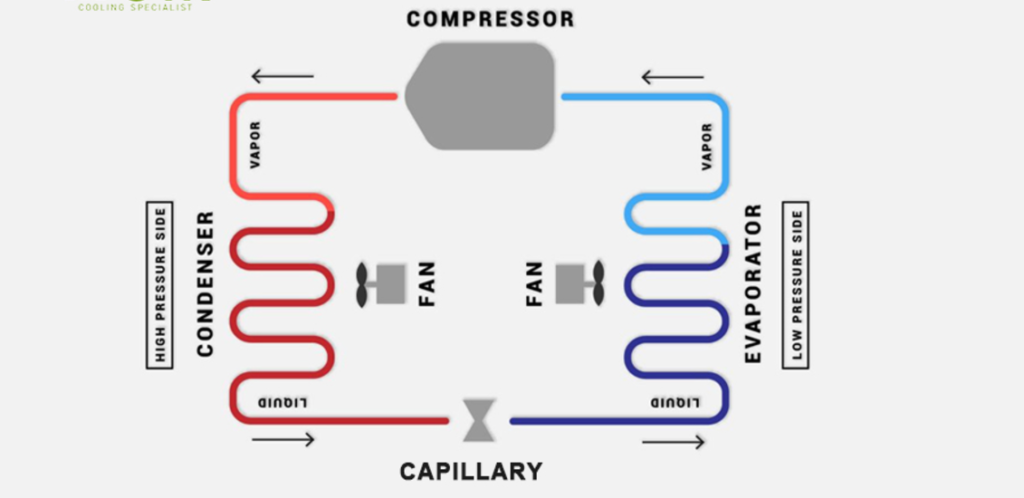

Unlike traditional HVAC systems, which are often bulkier and less adaptable, micro cooling systems are tailored to meet specific needs. They typically consist of a compact compressor, evaporator, condenser, and other essential components integrated into a single unit. This design allows them to be easily installed and maintained, making them perfect for many thermal management applications where space and lightweight are key parameters.

These systems are designed to provide localized cooling in small-scale environments, such as electronics cooling, medical devices, automative components and even in consumer products like mini refrigerators.

The importance of micro cooling systems can be summarized into several key points:

- Extend Product Lifespan: By maintaining optimal operating temperatures, micro cooling systems help prevent overheating and premature failure of electronic components.

- Enhance Performance: Precision cooling ensures that sensitive devices operate within their specified temperature ranges, maximizing their performance and reliability.

- Reduce Energy Consumption: Advanced micro cooling systems utilize energy-efficient technologies, contributing to lower operational costs and a reduced carbon footprint.

- Enable Miniaturization: The compact design of micro cooling systems allows for the development of smaller, more portable devices, pushing the boundaries of technology.

Applications of Micro Cooling Systems

The application of micro refrigeration systems spans a wide range of fields, from cooling electronic components to supporting medical devices and consumer electronics. The development of these systems is characterized by a focus on thermodynamic feasibility, innovative design considerations, and the exploration of new materials and technologies to meet the growing demand for compact, efficient, and environmentally friendly cooling solutions.

Below are some key applications where micro cooling technology excels:

1. Medical Equipment Cooling: In medical settings, maintaining precise temperatures is crucial for the proper functioning of equipment such as MRI machines, CT scanners, and laboratory instruments. Micro cooling systems ensure that these devices operate within optimal temperature ranges, enhancing their performance and longevity .

2. Electronics Cooling: With the increasing miniaturization of electronic devices, managing heat efficiently has become more challenging. Micro cooling systems are used to cool high-performance electronics like servers, data centers, and advanced computing hardware. They prevent overheating, which can lead to device failure or reduced performance .

3. Automotive Applications: In automotive engines, micro cooling systems help manage heat generated during operation. This ensures that engines run smoothly and efficiently, extending their lifespan and improving overall vehicle performance .

4. Food Industry: In retail environments like supermarkets and convenience stores, micro cooling systems are used to preserve perishable goods during transportation and storage. They maintain consistent temperatures, ensuring food safety and quality .

5. Personal Cooling Systems: For individuals working in hot environments or engaging in high-intensity activities, personal cooling systems offer relief from excessive heat. These systems can be integrated into protective gear like helmets or worn as wearable devices .

Development and Advancement of Micro Cooling Systems

The development and advancement of micro cooling systems have been driven by technological innovations that have enabled these systems to become more compact, efficient, and versatile. Micro refrigeration systems operate on principles similar to traditional HVAC systems but are scaled down to fit into smaller spaces, making them ideal for applications where space is limited or where high cooling efficiency is required.

The evolution of micro refrigeration systems has also seen the introduction of various types, including vapor compression refrigeration systems and liquid cooling systems, each with its own advantages for specific applications. For instance, vapor compression systems use refrigerants to cool components under atmospheric conditions, while liquid cooling systems offer flexible temperature control modules.

Despite these advancements, challenges remain in fully implementing these technologies in practical applications. Key issues include the difficulty of manufacturing reliable and efficient miniature compressors and the need for cost-effective production methods . However, ongoing research and development continue to address these bottlenecks, promising further improvements in the efficiency and applicability of micro refrigeration systems across various industries.

Select the Best Micro Cooling Systems

The latest advancements and best practices in micro cooling systems focus on addressing the increasing heat dissipation challenges posed by high-power density electronic devices. Several innovative approaches have been developed to enhance the efficiency and compactness of these cooling solutions: Microchannel Heat Sinks, Capillary-Enhanced Two-Phase Micro-Coolers, Embedded Microfluidic Cooling Systems, Thermoelectric Peltier Coolers, Vapor Compression Refrigeration Systems. These advancements collectively represent a shift towards more integrated, efficient, and compact cooling solutions that can meet the growing demands of modern electronic devices.

However, selecting the best micro cooling systems for specific applications involves a comprehensive analysis of various factors, including the type of application, heat flux, space constraints, power consumption, and the desired level of cooling efficiency. Based on the evidence provided, several key considerations and methodologies can guide the selection process:

1. Application-Specific Requirements: The first step is to understand the specific requirements of the application in terms of heat flux, size constraints, and performance metrics. For instance, high-power microelectronics may require advanced cooling solutions capable of handling high heat fluxes .

2. Cooling Technology Options: Various cooling technologies have been explored for micro applications, including vapor compression refrigeration , thermoelectric coolers (TECs) , microchannel coolers , and novel approaches like micro capillary groove evaporators . Each technology has its advantages and limitations depending on the application’s specific needs.

3. Performance Metrics: Key performance metrics include cooling capacity, thermal resistance, pressure drop, and efficiency. For example, vapor compression refrigeration systems have shown potential for small-scale applications with ammonia as a refrigerant leading to efficient cooling . Similarly, microchannel coolers have demonstrated high heat transfer coefficients and are suitable for applications requiring compact designs .

4. Optimization Techniques: Advanced optimization techniques, such as the entropy generation minimization criterion powered by the cuckoo search algorithm , can be employed to design optimal cooling systems tailored to specific applications. These techniques can help in selecting materials, coolant types, and system configurations that maximize cooling performance while minimizing energy consumption and system size.

5. Material and Coolant Selection: The choice of materials and coolants plays a crucial role in the effectiveness of cooling systems. For instance, using high thermal conductive materials like graphite and water-based colloids can enhance the thermal efficiency of microchannel heat sinks . Additionally, the use of nanoparticles in coolants has been shown to improve thermal performance .

6. Experimental Validation: It is essential to validate the theoretical designs and optimizations through experimental studies. Evidence from experimental analyses and characterizations provides insights into the practical performance and reliability of cooling systems under real-world conditions .

7. Integration and Miniaturization Challenges: For applications requiring integration within electronic packaging or other compact spaces, considerations around miniaturization and integration challenges become critical . The development of mesoscale vapor-compression refrigerators and other miniaturized cooling solutions addresses these challenges by offering scalable and efficient cooling options .

8. Future Trends and Innovations: Keeping abreast of emerging trends and innovations in cooling technology is vital for selecting the best cooling systems. For example, the exploration of liquid metal as a coolant for MEMS-based micro cooling devices represents a novel approach with promising cooling capabilities.

By considering these factors comprehensively, engineers can make informed decisions that lead to the selection of optimal cooling solutions tailored to the unique needs of their applications.

Exploring the Advantages of Moir Cooling

As independent global player and leading specialist in micro refrigeration sector, MOIR’s R&D team strive every day to develop innovative and sustainable technologies that meet the growing demand for compact, efficient, reliable, and environmentally friendly cooling solutions.

With over 30 years development and advancement, our factory has developed and manufactured a line up of miniature rotary compressors and micro cooling systems. Each of our refrigeration system is designed and built to guarantee maximum energy efficiency, maximum reliability and constant high performance over time. With a deep insight of the usage across various applications and our focus on customers, we’ve earned a position as a trustworthy and long-term partner with many OEM customers around the globe.

By combining application understanding, compressors, and package control expertise, we create custom solutions that meet customer needs and expectations.

1. Innovative Technology: Our micro cooling systems incorporate cutting-edge technology, including variable speed compressors and advanced refrigeration circuits. These features ensure precise temperature control and high efficiency, minimizing energy consumption .

2. Compact Design: MOIR’s systems are designed to be compact yet powerful. They can be easily integrated into existing setups without requiring significant modifications. This makes them ideal for applications where space is limited .

3. Environmental Responsibility: We prioritize eco-sustainability by using natural refrigerants like R290, which have no impact on the environment. Our systems are also designed to minimize energy consumption, contributing to a more sustainable future .

4. Reliability and Durability: Our micro cooling systems are built with military-level components, ensuring rock-solid reliability and durability. They are suitable for harsh environments and can withstand rigorous use without compromising performance .

5. Customization Options: We offers customized solutions tailored to specific needs. Whether you require a system for medical equipment cooling or personal cooling devices, we can design a solution that meets your exact requirements .

Conclusion

Micro cooling systems represent a significant advancement in thermal management technology. They offer unparalleled efficiency, flexibility, and reliability, making them essential for a wide range of applications. Most importantly, The advent of micro cooling systems based on micro compressor refrigeration technology is a game-changer for temperature control across various industries. Whether you’re in the medical, electronics, aerospace, or food preservation sector, micro cooling systems can help you achieve optimal performance and reduce operational costs.

At MOIR, we are dedicated to providing innovative compressor cooling solutions that meet the unique demands of various industries. Our team of experts is committed to innovation, customization, and sustainable practices, ensuring that our customers receive the highest quality products and services.By choosing MOIR, you can trust in the highest quality and performance for your micro cooling needs.

For more information on our products and how they can benefit your specific application, visit our website at moircooling.com or contact us directly at info@moircooling.com .

Reference 1: https://docs.lib.purdue.edu/iracc/1183/

Reference 2: https://ieeexplore.ieee.org/document/4135186)