Application and Challenges of Medical Skin Lasers

With the continuous development and improvement of medical aesthetics,skin lasers have become indispensable tools for a variety of treatments, ranging from hair removal and tattoo removal to skin resurfacing and wrinkle reduction. Laser treatment, characterized by its non-invasiveness, high precision, and short recovery period, has emerged as an ideal solution- active liquid cooling for various skin issues.

However, the heat generated during laser treatment cannot be overlooked as excessively high temperatures can not only cause discomfort but also damage skin tissue, potentially leading to burns. Therefore, addressing thermal control issues during laser treatment and maintaining stable and optimal laser performance throughout the procedure has become crucial for ensuring effective treatment and patient safety.

Thermal management poses additional challenges due to size constraints, power consumption requirements, and noise limitations. That’s where active liquid cooling comes in. As a compact cooling solution provider with a strong background in micro refrigeration technology, we at Moir Cooling understand the intricacies of active liquid cooling for medical skin lasers and its transformative impact on the industry.

The Importance of Temperature Control in Medical Skin Lasers

Medical skin lasers work by emitting intense, focused beams of light that target specific skin conditions. The light is absorbed by the targeted tissue, causing it to heat up and break down. This process can be highly effective, but it also generates a significant amount of heat. If not properly managed, this heat can lead to discomfort for the patient, damage to surrounding tissues, and even potential complications.

Temperature control is therefore essential for ensuring the safety and efficacy of medical skin lasers. It allows for more precise targeting of the desired tissue while minimizing damage to surrounding areas. Active liquid cooling is one of the most advanced and effective methods of temperature control in medical skin lasers.

Active Liquid Cooling: The Key to Solving Thermal Control Issues in Medical Skin Lasers

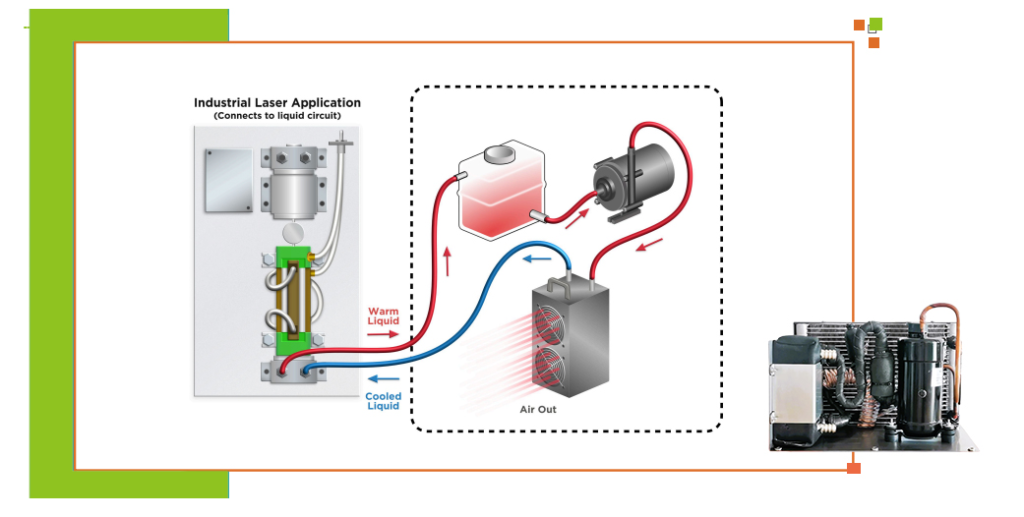

Active liquid cooling is a technology that uses a refrigerant fluid to actively cool the laser’s handpiece and the treated tissue. The refrigerant fluid circulates through a closed loop system, absorbing heat from the laser’s components and the treated area. This heat is then dissipated through a heat exchanger, maintaining a consistent and safe temperature throughout the procedure.

To ensure the smooth progress of laser treatment and maximize skin protection, refrigeration technology has been introduced into the field of skin laser treatment. The core function of this technology is to rapidly and effectively absorb and transfer excess heat generated during laser irradiation, preventing excessive surface temperatures on the skin. This is particularly important in applications such as laser hair removal and the treatment of pigmented lesions, as it not only reduces patient discomfort during the procedure but also enhances the efficiency and safety of the treatment.

The Benefits of Active Liquid Cooling

One of the most significant benefits of active liquid cooling is its ability to enhance precision and safety during medical skin laser treatments. By maintaining a consistent temperature, active liquid cooling ensures that the laser’s energy is delivered with pinpoint accuracy. This minimizes the risk of damage to surrounding tissues, reducing discomfort and potential complications for the patient.

Improved Patient Comfort

Another key benefit of active liquid cooling is its ability to improve patient comfort during treatment. The cooling effect of the refrigerant fluid numbs the treated area, reducing pain and discomfort. This allows for longer treatment sessions and more aggressive treatment plans, leading to better overall outcomes for the patient.

Increased Efficiency and Treatment Speeds

Active liquid cooling also increases the efficiency and speed of medical skin laser treatments. By maintaining an optimal temperature, the laser’s components can operate more effectively, reducing the time required for each treatment. This not only enhances patient satisfaction but also allows for more treatments to be performed in a shorter period of time, increasing the profitability of the practice.

Longevity of Laser Equipment

Lastly, active liquid cooling helps to extend the longevity of the laser equipment. By preventing overheating, it reduces wear and tear on the laser’s components, leading to fewer repairs and replacements. This can significantly reduce the overall cost of ownership for the practice.

Types of Active Liquid Cooling Technology

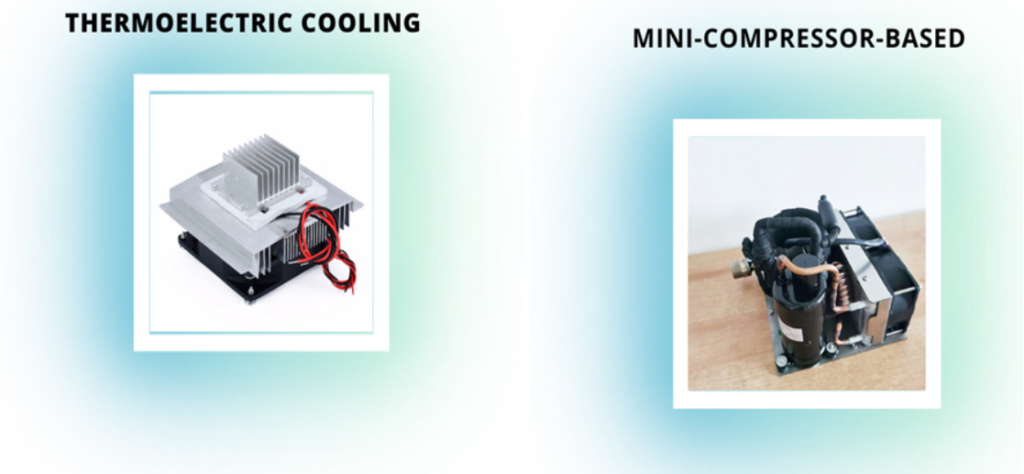

Various types of cooling systems are used in medical lasers to maintain the temperature of the sample during testing. The choice of cooling system depends on the specific requirements of the rheological test and the sample being tested. Common cooling systems used in skin lasers include:

Peltier Element Cooling

Peltier element cooling technology utilizes the Peltier effect to achieve thermal energy transfer. When an electric current passes through the Peltier element, it generates a heat transfer phenomenon, where heat is transferred from one side of the current to the other. Peltier elements are compact in structure and suitable for use in small and portable laser devices.

Vapor Compression Cooling

Vapor compression technology utilizes the principles of evaporation and condensation to achieve thermal energy transfer. It has strong cooling capabilities and can be applied to laser devices of various scales, from small to large.

Liquid Nitrogen Cooling

It can be used as a cooling medium to rapidly cool samples to very low temperatures, reducing the temperature to around -196℃. It is commonly used for samples that require extremely low temperatures, such as those used in cryogenic testing.

Introduction to Miniaturized Vapor Compression Cooling

Compared to traditional Peltier element cooling technology, micro vapor cooling technology exhibits higher cooling capacity and more uniform temperature distribution. It provides greater refrigeration capacity while reducing reliance on cooling media, system complexity, and volume. Additionally, micro vapor cooling technology offers advantages in energy efficiency, environmental friendliness, and reliability, meeting the demands of various application scenarios.

Moir’s active liquid cooling technology – mini water chiller and direct expansion system, is a type of circulatory cooling subsystem for chilling recirculated water. Because of its benefits of providing fast, effcient and precise cooling to desired temperature, it is an ideal option for medical laser applications. With natural R290 refrigerant and twin-motor configuration, our miniature compressor based water chiller delivers higher heat pumping capacity, and reduced noise for quieter operation. Plus, it is compact size offers a smaller and lighter package to bring the footprint to minimize. This innovativer chiller is able to cool up to 600W and maintain a temperature range from to -10°C to 40°C .

New Green Refrigerants – Natural R290

Currently, there is a push to develop refrigerants with lower Global Warming Potential (GWP). Government and environmental regulations have implemented measures requiring the use of more environmentally friendly alternatives in refrigeration systems. These alternative refrigerants include Hydrofluoroolefins (HFOs), natural refrigerants (such as ammonia and carbon dioxide), and hydrocarbons (such as isobutane and propane).

When selecting a recirculating cooler for skin lasers, it is essential to carefully evaluate various options and choose a system that not only meets application requirements but also complies with relevant government and environmental regulations. The specific type of refrigerant used depends on the specific needs and requirements of the laser equipment.

To adapt to changing government regulations, Moir Cooling utilizes the more environmentally friendly R290 refrigerant, which has a Global Warming Potential (GWP) of 0 when compared to traditional Hydrofluorocarbons (HFC) refrigerants. The platform also complies with UL61010-1 or IEC 61010-1 laboratory safety standards.

Our Expertise in Active Liquid Cooling for Medical Skin Lasers

At Moir Cooling, we specialize in the design and manufacture of compact cooling solutions for medical skin lasers. Our team of experts has a deep understanding of micro refrigeration technology and the unique challenges faced by medical aesthetic professionals. We have developed a range of active liquid cooling systems(including Plate mini water chiller, Coaxial mini chiller system, direct refrigerant systems) that are tailored to meet the specific needs of medical skin lasers.

Customizable Solutions

We offer customizable solutions that can be tailored to fit any medical skin laser on the market. Our systems are designed to be compact, lightweight, and easy to integrate into existing equipment. This allows for seamless integration without compromising the performance or aesthetics of the laser.

Advanced Technology

Our active liquid cooling systems utilize the latest advancements in micro refrigeration technology. We use high-efficiency and sustainable R290 refrigerant fluids and innovative heat exchanger designs to maximize cooling performance while minimizing energy consumption. This ensures that our systems are both effective and cost-efficient.

Reliable and Durable

We build our active liquid cooling systems to be reliable and durable. They are rigorously tested and validated to ensure that they can withstand the demands of medical skin laser treatments. This ensures that our customers can trust our solutions to deliver consistent performance over the long term.Case

Studies: Real-World Applications of Active Liquid Cooling

To demonstrate the real-world impact of active liquid cooling for medical skin lasers, we have compiled a selection of case studies from our customers. These case studies highlight the benefits of active liquid cooling in a variety of medical aesthetic applications.

Case Study 1: Hair Removal

One of our customers from Italy, an OEM manufacturer of medical aesthetic laser equipment, was facing with space- and cooling power constraint issues by the use of current Peltier cooling technology. The thermoelectric coolers cannot deliver the required cooling capacity of 300~400W due to compact housing. The overhot that cannot be effectively removed during the laser operation seriously jeopardises the patient’s comfort.

After switching to MOIR’s active liquid cooling with our mini compressor technology – MC02824E-PN6, the customer noticed a significant improvement in maintaining the cooling performance and treatment speeds in the same size housing. The system was able to maintain a consistent temperature throughout the procedure, allowing for longer treatment sessions and more aggressive treatment plans.

Case Study 2: Tattoo Removal

Another customer from Brazil, a hair removal clinic, was experiencing challenges with laser damage to surrounding skin tissue. The heat generated by the laser was causing unwanted side effects, such as redness and swelling. By integrating our active liquid cooling system into their equipment, the clinic was able to reduce the risk of damage to surrounding tissues and improve patient satisfaction. The system’s cooling effect also numbed the treated area, reducing discomfort during the procedure.

Conclusion

As the demand for skin laser treatment continues to grow, the requirements for active liquid cooling technology are also increasing. Micro vapor compression technology, as an emerging cooling technology, holds promising application prospects. In the future, with continuous technological advancements and cost reductions, this technology is expected to gain wider application in the field of medical aesthetic skin lasers. Simultaneously, as the safety and effectiveness requirements for skin laser treatment continue to increase, micro vapor compression technology is poised to become an important safeguard measure, providing patients with a safer and more comfortable treatment experience.