In today’s world, where energy efficiency and sustainability are paramount, the components of our cooling systems play a crucial role. Among these, compressors stand out as the heart of HVAC systems, directly influencing performance and energy consumption. Recent advancements have spotlighted small rotary compressors, particularly those developed by Moir Cooling, for their remarkable contributions to energy-efficient cooling solutions.

Introduction: The Role of Compressors in Modern Cooling Systems

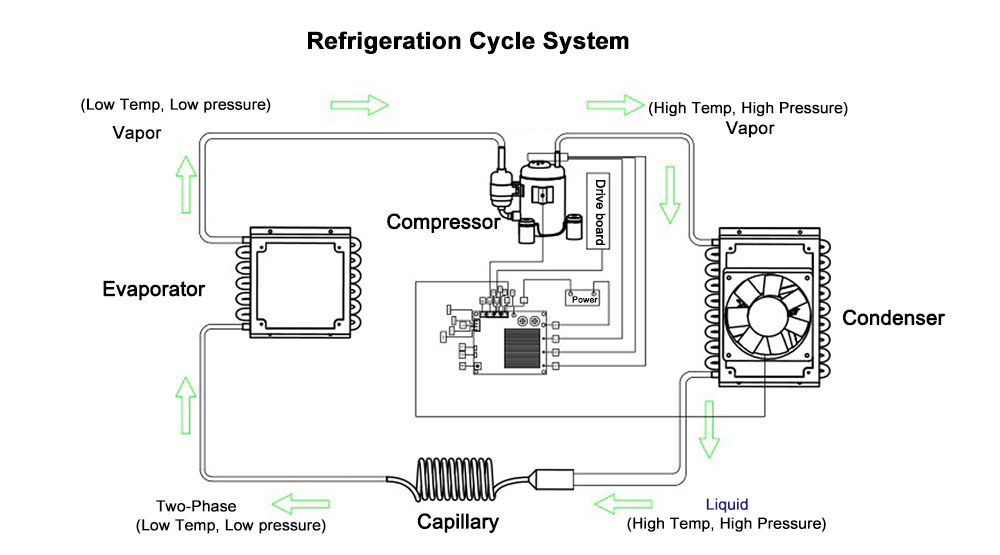

Compressors are integral to HVAC (Heating, Ventilation, and Air Conditioning) systems, responsible for pressurizing refrigerants to facilitate heat exchange. This process is essential for both cooling and heating applications, making compressors the backbone of climate control systems in residential, commercial, and industrial settings. The efficiency and design of these compressors significantly impact the overall energy consumption and effectiveness of HVAC systems.

Defining Small Rotary Compressors: Compact Powerhouses

Small rotary compressors are compact devices designed to compress refrigerants using a rotating mechanism. Unlike traditional piston compressors, which rely on the reciprocating motion of pistons, rotary compressors utilize continuous rotational motion, leading to smoother operation and reduced vibration. Their compact size makes them ideal for applications where space is limited, without compromising on performance.

The Science Behind Rotary Compression: How It Works

Rotary compressors operate by trapping refrigerant between the rotating components and the compressor casing, gradually reducing its volume and increasing its pressure. This continuous compression cycle differs from the intermittent strokes of piston compressors, resulting in more consistent pressure and flow. The design simplicity of rotary compressors often leads to fewer moving parts, reducing maintenance needs and enhancing reliability.

Small Rotary Compressor Advantages

1. Energy Efficiency Unveiled: The Mechanics of Savings

The continuous operation of rotary compressors contributes to their energy efficiency. By maintaining a steady compression process, they minimize the energy losses associated with the start-stop cycles of traditional compressors. This consistent operation not only reduces energy consumption but also enhances the lifespan of the compressor by reducing mechanical stress.

2. Variable Speed Technology: Matching Demand with Supply

Modern advancements have introduced variable speed technology to rotary compressors. This innovation allows the compressor to adjust its operating speed in real-time, aligning with the cooling demand. By modulating speed, variable speed rotary compressors avoid unnecessary energy consumption during periods of low demand, leading to substantial energy savings and more precise temperature control.

3. Compact Design, Big Impact: Space and Material Savings

The reduced size of small rotary compressors offers significant advantages in HVAC system design. Their compact footprint allows for more flexible installation options, especially in applications with space constraints. Additionally, the material savings from their smaller size contribute to environmental benefits, aligning with sustainable practices by reducing the resources required for manufacturing and transportation.

4. Quiet Operation: Enhancing User Comfort

One of the notable benefits of rotary compressors is their quiet operation. The continuous rotational motion produces less noise compared to the pulsating action of piston compressors. This reduction in noise levels enhances comfort in residential and commercial environments, making rotary compressors a preferred choice for applications where silence is valued.

5. Durability and Longevity: Built to Last

The robust construction and fewer moving parts in rotary compressors contribute to their durability. This design minimizes wear and tear, leading to extended operational life and reduced maintenance requirements. For instance, MOIR Cooling’s miniature rotary compressors are engineered for reliability, ensuring consistent performance over prolonged periods.

Applications Across Industries: Versatility in Action

Small rotary compressors have found applications across various industries due to their efficiency and compact design.

In residential settings, they are used in air conditioning units and refrigerators.

Commercially, they are employed in dehumidifiers and display cases.

Industrially, their reliability makes them suitable for process cooling and specialized equipment.

This versatility showcases their adaptability to diverse cooling needs.

Environmental Benefits: A Greener Choice

The energy efficiency of rotary compressors translates to lower greenhouse gas emissions, as reduced energy consumption lessens the demand on power plants, many of which rely on fossil fuels. Additionally, Moir Cooling develops the compressors compatible with environmentally friendly refrigerants R290, further reducing the ecological footprint of cooling systems.

Cost Implications: Upfront Investment vs. Long-Term Savings

While the initial cost of small rotary compressors may be higher compared to traditional models, the long-term energy savings often justify the investment. The reduced operational costs, combined with lower maintenance expenses due to their durable design, result in a favorable return on investment over the compressor’s lifespan.

Installation Considerations: Seamless Integration

Integrating small rotary compressors into existing or new HVAC systems requires careful planning. Factors such as compatibility with system components, appropriate sizing, and proper installation techniques are crucial for optimal performance. Collaborating with manufacturers like Moir Cooling can provide valuable guidance to ensure seamless integration and operation.

Technological Innovations: The Future of Rotary Compressors

The future of rotary compressors is marked by continuous technological advancements. Developments in materials science, precision manufacturing, and smart controls are leading to compressors that are even more efficient, quieter, and adaptable. These innovations promise to further enhance the role of rotary compressors in sustainable cooling solutions.

Comparative Analysis: Rotary vs. Other Compressor Types

When compared to reciprocating (piston) and scroll compressors, rotary compressors offer unique advantages.

1. Rotary Compressors

Rotary compressors utilize a rotating mechanism to compress refrigerant, resulting in continuous compression with minimal pulsation. This design leads to smoother operation and reduced vibration. Notably, rotary compressors have fewer moving parts, which enhances reliability and reduces maintenance requirements.

They provide a balance between efficiency and cost, with smoother operation and reduced noise levels.

2. Reciprocating (Piston) Compressors

Reciprocating compressors operate using a piston-cylinder mechanism, compressing refrigerant through a back-and-forth motion. While they are widely used and capable of achieving high pressures, they have several drawbacks:

- Efficiency: The reciprocating motion and numerous moving parts result in higher energy losses due to friction.

- Noise and Vibration: The nature of their operation leads to increased noise levels and vibration, making them less suitable for environments where quiet operation is essential.

- Maintenance: The complexity and higher number of components necessitate more frequent maintenance, potentially increasing operational costs over time.

Scroll compressors may offer slightly higher efficiencies, rotary compressors often present a more cost-effective solution with comparable performance, especially in applications where space and noise are critical considerations.

3. Scroll Compressors

Scroll compressors consist of two interleaved spiral-like vanes, with one fixed and the other orbiting eccentrically. This configuration offers several benefits:

- Efficiency: The continuous compression process and minimal clearance volume result in high volumetric efficiency.

- Noise and Vibration: The smooth, continuous motion leads to quieter operation with reduced vibration, making them suitable for noise-sensitive applications.

- Reliability: With fewer moving parts, scroll compressors tend to have enhanced durability and lower maintenance requirements.

However, these advantages come at a higher initial cost compared to rotary compressors.

Real-World Success Stories: Efficiency in Practice

The transition to small rotary compressors has yielded significant benefits across various industries, demonstrating their practical advantages in real-world settings.

Case Study 1: Beverage Packaging Plant

A beverage packaging plant faced escalating energy costs and sought to improve the efficiency of its compressor room. By conducting a thorough assessment, the plant identified opportunities to optimize its compressed air system. Implementing energy-efficient compressors led to reduced energy consumption and maintenance costs, while still meeting increased air demands. ( from reliableplant.com )

Case Study 2: Medical Laser Equipment Manufacturer

A manufacturer of medical laser equipment experienced inefficiencies and space shortage with their existing compressor setup. An Air Demand Analysis revealed that a single 500W(cooling capacity) compressor with adequate storage could meet the plant’s demand more efficiently. Upgrading to this optimized system resulted in significant energy and maintenance cost savings, while maintaining steady plant pressure and sufficient space.

Choosing the Right Compressor: Factors to Consider

Selecting the appropriate small rotary compressor for your cooling system involves careful consideration of several key factors:

- Cooling Requirements: Assess the specific cooling demands of your application, including the required temperature range and heat load. This ensures the compressor’s capacity aligns with your system’s needs.

- Compressor Compatibility: Ensure the compressor is compatible with your existing HVAC system components, including refrigerants and control systems. Compatibility minimizes integration challenges and enhances overall efficiency.

- Space Constraints: Evaluate the available installation space. The compact design of small rotary compressors offers flexibility, but accurate measurements are essential to ensure a proper fit.

- Energy Efficiency: Prioritize compressors with high energy efficiency ratings. Features like variable speed technology can significantly reduce operational costs by adjusting compressor speed to match cooling demands.

- Noise Levels: Consider the operational noise levels, especially in environments where quiet operation is crucial. Opting for compressors known for reduced noise can enhance user comfort.

- Reliability and Maintenance: Research the compressor’s track record for durability and ease of maintenance. Reliable compressors with longer lifespans and minimal maintenance requirements contribute to cost savings over time.

Conclusion: Embracing Efficiency with Small Rotary Compressors

Small rotary compressors, such as those offered by Moir Cooling, represent a significant advancement in cooling system technology. Their compact design, energy efficiency, quiet operation, and versatility make them an excellent choice for energy-conscious consumers and businesses alike. By carefully assessing your specific cooling requirements and considering the factors outlined above, you can select a compressor that not only meets your needs but also contributes to a more sustainable and cost-effective future.

Embracing these advanced compressor technologies is a proactive step toward optimizing energy consumption and enhancing the overall performance of cooling systems across various applications.