- +86 0755-86614858

- info@moircooling.com

- 24/7 Customer Service

MCU600 Coaxial-C Mini Chiller

Small Footprint While Excellent Cooling Power for Portable & Mobile Refrigeration

The MCU600 Coaxial Mini Chiller, is a compact refrigeration system, delivering up to 600 watts of cooling power based on temperature. It is designed for use in various challenging environments including medical facilities, industrial settings, electric vehicles, laser systems, laboratories, and transport refrigeration. This self-contained water loop cooling system integrates essential refrigeration components into a single package. It includes a mini DC compressor with its drive, a condenser, a capillary tube, and a plate-type evaporator.

These compressor-based chillers are noted for their compactness, lightweight design, and high efficiency, making them powerful engines for cooling applications. When correctly installed, the mini chiller unit utilizes vapor compressor technology to efficiently cool a circulating coolant, ensuring stable operation and longevity of the system. It operates on low power consumption, making it an ideal solution for thermal management needs. The unit is powered by 24V DC power supplies, providing flexibility for integration into different systems.

Unique Benefits: Energy efficiency, low maintenance cost, exceptional cooling capacity, ultra-compact size, low noise & vibration, fast and easy integration

MC02824C-P6 Mini Chiller

- Refrigerant: Natural R290

- Nominal Voltage: 24V DC

- Cooling Capacity: 100~600W (2,047 Btu)

- Motor Speed: 1,800~4,800rpm

- Maximum Current: 16 Amps

- Weight: 3.5 kg (7.7 lbs)

- Dimension: 203 x 219 x 175mm

MC02824C-P4 Mini Chiller

- Refrigerant: R134a

- Nominal Voltage: 24V DC

- Cooling Capacity: 100~550W (1,876 Btu)

- Motor Speed: 2,100~4,500rpm

- Maximum Current: 12 Amps

- Weight: 3.5 kg (7.7 lbs)

- Dimension: 203 x 219 x 175mm

MC02848C-P4 Mini Chiller

- Refrigerant: R134a

- Nominal Voltage: 48V DC

- Cooling Capacity: 100~600W (2,047 Btu)

- Motor Speed: 1,800~6,300rpm

- Maximum Current: 12 Amps

- Weight: 3.5 kg (7.7 lbs)

- Dimension: 203 x 219 x 175mm

It's the Little Things that Make All the Difference

Quality has many facets. The Coaxial-type chiller unit integrates cutting-edge technology and components from trusted suppliers, which significantly contribute to its performance and reliablity in industrial, commercial refrigeration, and thermal management applications.

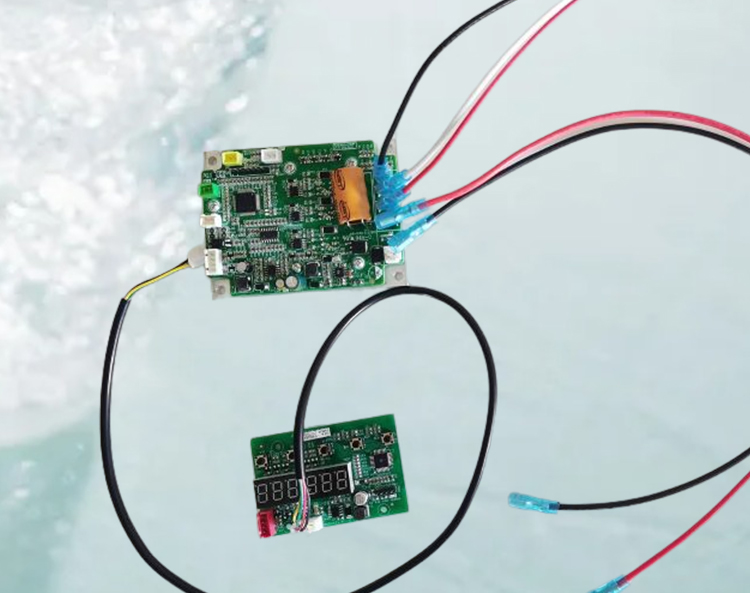

Featured an advanced inverter board, it allows the refrigeration device’s speed to be regulated from the upper system by frequency or analog signal. This advanced control system ensures precise temperature regulation and adaptability to different operational requirements, enhancing overall system performance.

BLDC Inverter Compressor

Small footprint, variable speed, direct current inverter electric compressor, featuring outstanding cooling power and quiet operation.

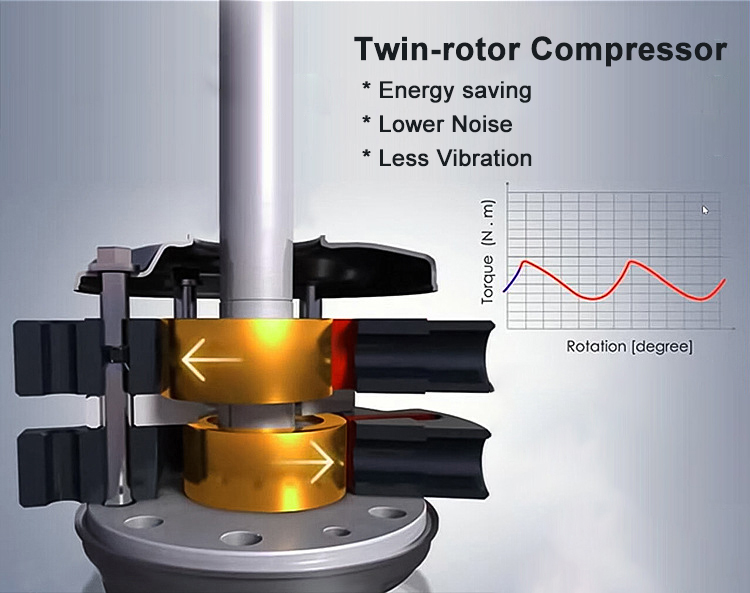

Twin-Cylinder Configuration

Offers twice the efficiency of a single series, with reduced vibration, the best options for challenging applications across medical, laser, etc.

Advanced Drive Controller

Provides variable capacity and load-following capabilities for accurate temperature regulation and maximum efficiency, thereby minimizing electricity loss.

Eco-friendly Refrigerant R290

Equipped with natural R290 configuration, posing no negative impact on the environment while providing superior thermal properties.

Effective Heat Exchangers

Conbined with the smallest condenser and Coaxial-type evaporator in Titanium material, offering high heat dissipation and absorption.

Less Maintenance Design

Hermetically sealed subsystem contains all the core components into a package mounting on a chassis, with no user maintenance.

Coaxial-C Mini Chiller - Delivering the Highest Cooling Performance in the Smallest Package

The Coaxial-type chiller module is a recirculating chiller subsystem. It is tailored to the needs of engineers and system integrators in demanding direct current applications such as medical laser equipment, automotive, battery thermal management, and food & beverage cooling. This DC cooling unit equipped with variable-speed DC compressors is to optimize the smooth operation and prolong the lifespan of air conditioning & refrigeration devices. The benefits of a coaxial chiller unit includes an ultra-small radiator and high heat flux. Thanks to its extremely compact size, this compact chiller module can be easily integrated into user’s system while ensuring an unmatched cooling performance with the micro refrigeration DC compressor.

Extremely Small Footprint

Containing all small key components ( mini compressor, condenser, evaporator, capillary) into a package, the mini chiller unit is often sized less than a shoebox. It allows our partners to easily integrate our thermal solutions into small spaces inside their chassis, devices, or consoles. Because of the chiller’s compactness, they are widely employed in many critical applications where space and weight are crucial, such as vertical micro-farming setups, beverage dispensers, portable medical laser devices, and more.

Excellent Cooling Power

Utilizing the R290 refrigerant, renowned for its exceptional thermal conductivity and heat absorption capacity, the coaxial liquid chiller units guarantee superior heat transfer performance. The DC-powered refrigerated compressor effectively circulates the refrigerant, efficiently extracting heat from the space, thus ensuing critical equipment funtions optimally. Additionally, its high COP exceeding 3.0W/W significantly reduces power consumption, leading to substantial savings in operating costs.

High Energy-Efficiency

Adopting our variable-capacity, twin-cylinder compressor, the coaxial cooling systems offers higher efficiency and lower vibration than any other small thermal solution on the market. Unlike the products based on traditional fixed compressor that constantly runs at 100% speed, this dc small chiller from inverter rotary compressors can be adjusted the speed as it needs for cooling, saving significantly amounts of electricity. The thermoelectric-based systems consume up to 5 times more power than MOIR’s cooling systems.

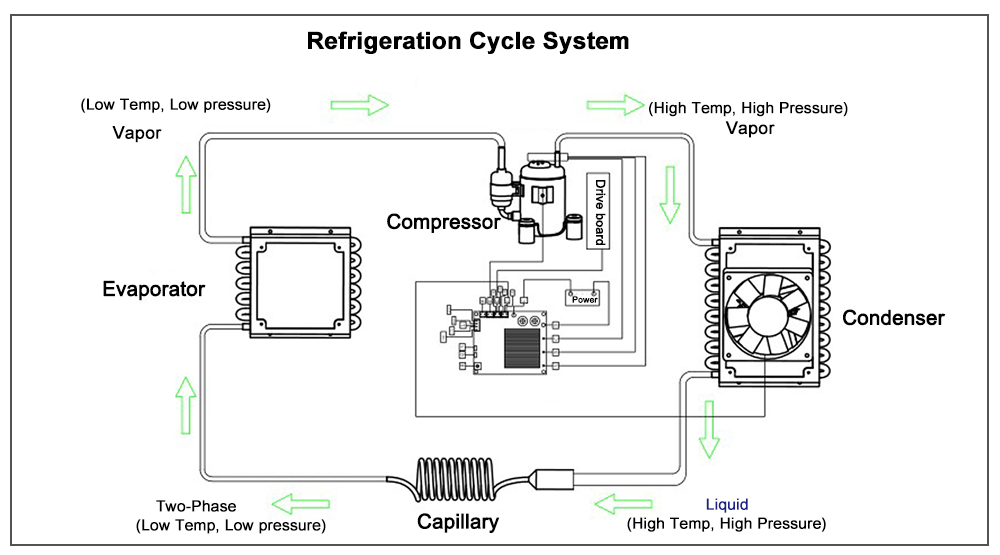

How MOIR Mini Chiller Unit Work?

The Mini Chiller Unit stands as the pivot of the variable-speed compressor cooling system. Upon proper installation, this compact system utilizes vapor cooling technology to chill a circulating coolant. Consituting the essence of the liquid refrigeration system, the dc small chiller integrates a compressor, evaporator, condenser, drive board, and other electronic components. Additionally, it necessitates a pump, reservoir, and control signal for its operation. The mini DC rotary compressor, holds a significant position in today’s market, being extensively utilized in numerous small and portable cooling systems.

Vapor compression circulatory refrigeration is a phase-change heat transfer process. Within the refrigeration cycle, the compressor draws in low-temperature, low-pressure refrigerant vapor from the evaporator and compresses it, reducing its volume to achieve high-temperature, high-pressure conditions. This vapor then travels to the condenser where heat is expelled to a cooling medium like water or air. The high-temperature, high-pressure liquid subsequently enters a throttling device, experiencing a pressure drop. The low-temperature refrigerant exiting the throttling device flows into the evaporator, where it encounters a heat source. The heat from this source boils off the refrigerant through phase change, transforming it back into a low-temperature, low-pressure vapor that is then reabsorbed by the compressor, completing the refrigeration cycle.

The mini chiller module is a circulatory cooling subsystem. All refrigeration parts are well integrated into one unit, delivering the highest cooling capacity in the smallest package. It provides chilled water for circulation through water pipes, and its compact size and lightweight design offer exceptional portability.

Engineering Services - Tailored Solutions that Maximize Proposed Strategies

Apart from the off-the-shelf mini cooling units, we offer you individually optimized system solutions. Whether small water chiller unit, micro air conditioning unit, or direct expansion system operating at LBP/MBP/HBP applications. If you cannot find the product that meets your desire, we can work out an optimum thermal solution for all your requirements. In this context, you can rely on our many years of experience in the small portable cooling sector. You profit from our high process and quality level, and our know-how in concept development, thermal modeling, and electrical design.

To get started for a custom solution, the below information would be needed:

1. What purpose you are looking to achieve?

2. What’s the cooling capacity required?

3. What cooling approach is desired: air cooling, liquid cooling, or direct refrigerant cold plate?

4. What is the cold side temperature( delivered air, coolant, or cold plate surface)?

5. What is the operating ambient temperature range?

6. Is there any size constraint?

7. Are there any other constraints or requirements?