Background

It is commonly known that laser systems generate significant amounts of heat during operation. This heat can originate from various sources, including the laser medium itself, the power supply, and optical components. If not effectively dissipated, this heat can lead to thermal distortions, affecting the beam quality and stability. This is because the efficiency of this equipment is typically well below 50%. This implies that even in optimal conditions, a laser generating 500 watts of light power would require dissipating at least an equivalent amount of waste heat, potentially even more. Consequently, the total incoming power to such a system would amount to 1 kW, with half directed towards laser light production and the remainder dissipated as heat. Regardless of their size or efficiency, a form of effective cooling is crucial for all lasers.

Solution Alternatives Overview

When it comes to laser cooling, there are two broad categories: active cooling and passive cooling. Passive cooling methods, such as heatsinks and fans, rely on natural convection and radiation to dissipate heat. While these methods may be suitable for low-power or non-critical applications, they often fall short in high-performance laser systems.

For applications with higher power outputs, high ambient temperatures, or lasers that are particularly sensitive to temperature variations, a pumped loop system, can be employed to effectively reduce the temperature within the laser. The utilization of liquid mediums in this process is highly efficient in removing heat from the laser, and subsequently dispersing it into the surrounding air. Nevertheless, the diode within the laser will inevitably maintain a higher temperature than the ambient air.

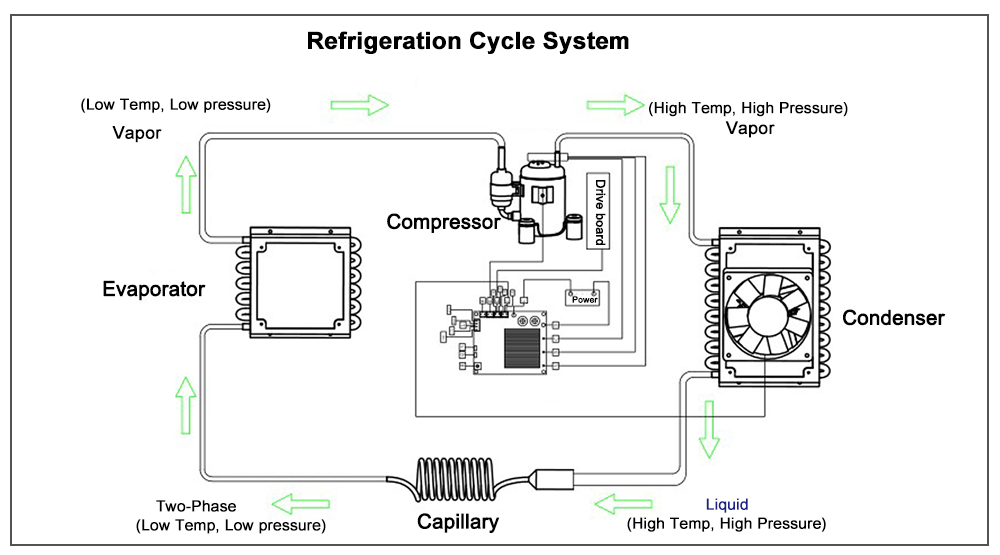

On the other hand, active cooling methods actively remove heat from the system. Compressor-based cooling systems are a prime example of active cooling. They use a refrigerant cycle, typically employing a compressor, condenser, expansion valve, and evaporator, to transfer heat away from the laser and dissipate it into the surrounding environment. This compressor-driven can also be controlled to maintain the required temperature as the power output of the laser rises and falls. The standard laser cooling system is a chiller that ensures a consistent temperature in the coolant flow of a closed-loop system.

Advantages of Compressor-Based Cooling System for Lasers

1. High Heat Removal Capacity

Compressor-based liquid chillers are capable of removing significantly more heat than passive cooling methods. This is due to the refrigerant cycle’s ability to efficiently transfer heat from the laser to a remote heat exchanger, allowing for effective dissipation into the atmosphere. This high heat removal capacity is crucial for high-power lasers that generate large amounts of heat during operation.

2. Precise Temperature Control

The liquid cooling systems based on compression technology offer precise temperature control, enabling users to maintain the laser within its optimal operating temperature range. This precision is achieved through the use of temperature sensors and control algorithms that monitor and adjust the cooling process accordingly. Precise temperature control is essential for preserving beam quality, stability, and the overall performance of the laser system.

3. Reliability and Durability

Compressor-based cooling systems are designed for continuous, reliable operation. The refrigerant cycle is enclosed within a closed loop, minimizing the risk of contamination or leaks. Additionally, the use of high-quality components and robust construction ensures durability and long-term performance.

4. Flexibility and Scalability

Compressor-based cooling systems offer flexibility and scalability, adapting to different laser power levels and cooling requirements. By adjusting the refrigerant flow rate, compressor speed, and other parameters, the cooling capacity can be tailored to meet the specific needs of the laser system. This scalability allows for cost-effective solutions that can be easily scaled up or down as required.

5. Environmental Friendliness

Modern compressor-based cooling systems often employ eco-friendly refrigerants like R290 that comply with environmental regulations. This ensures that the cooling system not only meets the performance requirements of the laser but also contributes to sustainable operations.

MOIR Compressor-based Cooling Systems Solution

At the beginning of the design process, the important question is, ” What type of cooling is the optimal solution for the application?”. It is advisable to make these decisions in the initial stages of the design process, ensuring that the space and power requirements are taken into account as the assembly is planned and organized.

MOIR boasts a comprehensive range of cooling modules that cater to various industries, from medical, and laboratory, to industrial to electric vehicles. Our active, compressor-driven cooling modules effectively address diverse cooling challenges.

Configurated with a Nickel-blazed stainless steel plate, MOIR liquid cooling system can be compatible with DI water ( deionized water). Unlike most players’ chiller modules that only work for water, and glycol-water mixtures, Moir mini cooling units are appreciated for laser cooling, especially for the medical market. The nickel-blazed plate evaporator heat exchanger can avoid galvanic corrosion problems for DI water applications and ensure the equipment’s safety and long lifespan operation.

Plus, based on our manufactured miniature twin-motor compressor technology, MOIR compressor-driven liquid chiller unit can benefit the laser equipment with space-saving, energy-saving, and cost-saving. The twin-cylinder compressor configuration delivers twice the efficiency of the single series, with reduced vibration and lower operation.

As laser technology continues to evolve and power levels increase, the importance of an efficient and reliable cooling system becomes even more apparent. Nowadays, laser cooling applications vary widely, encompassing military-grade systems operating in ambient temperatures of 55°C to industrial manufacturing equipment designed for round-the-clock operation on factory floors. Other scenarios include cooling laser diodes in lab equipment, and cooling the skin in laser medical aesthetics applications.

The cold-side temperature of MOIR cooling systems can be customized to range from 55°C down to -20°C,depending on specific requirements. Apart from our off-the-shelf solution, we offer bespoke solutions for your laser projects. Contact us for your cooling needs, our engineering team will work closely with you to make your ideas into reality.